28

2022

-

11

How to choose sponge sandpaper

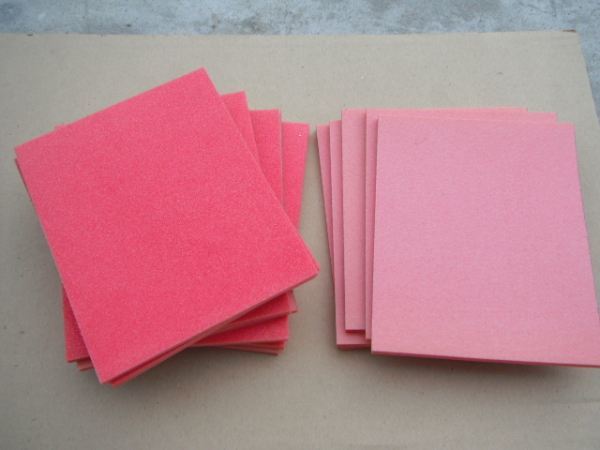

Sponge sandpaper is a strip-shaped tool used for grinding and polishing by being bonded to flexible materials such as paper and cloth through abrasives. Sponge sandpaper is composed of substrates, abrasives and binders. The base materials of sponge sandpaper for furniture production are cloth and paper. The paper base is made of a belt base made of specially processed high-strength paper as a sponge sandpaper. The price of sponge sandpaper with paper base is 1/3-2/3 lower than that of sponge sandpaper with cloth base.

The paper base is relatively hard and can grind a high-finish surface. Paper based sponge sandpaper is used in fine grinding and ultra-fine grinding. The cloth base has higher strength than the paper base and is less sensitive to temperature and humidity than the paper base. It will not lose its stability due to the increase of temperature and humidity. The durability of the cloth sponge sandpaper is much higher than that of the paper base. The more commonly used abrasives in furniture production are aluminum oxide, silicon carbide, aluminum zirconia, garnet, and hand sandpaper. Glass sand is used as the abrasive, which has its own characteristics.

Coarse grinding, large plasticity, large grinding area, choose coarse particle size in order to avoid embedded chips, the workpiece is relatively soft, etc.; fine grain is selected for fine grinding and hard workpiece. Abrasives are bonded in the tape base through adhesives. The binder should have strength, elasticity, heat resistance, water resistance, etc. The more commonly used binders are animal glue and synthetic resin. Animal glue is not water-resistant, and synthetic resin has strong water resistance. Water-resistant sponge sandpaper uses water-resistant synthetic resin as primer and double glue for strict waterproof treatment. According to the role of tape base, abrasive and binder, combined with the requirements of processing objects and process technology, choose the tape base, abrasive particles and binder that suits you, and the requirements of grinding processing can be achieved.

Related news

The difference between sponge sandpaper and general sandpaper

2022-11-28

Basic Principles of Sandpaper

2022-11-28

Fax : +86-533 8437777

ADD: NO.17 YI HE ROAD,GUOLI,HUAN TAI,ZIBO,SHANDONG,CHINA